Series 1500

3.Custom Features

Date : 2015-08-01 22:37|

Materials of Construction

|

|

||

|

|

|||

|

Drive System Options • Standard BALTIDRIVE® Power Train The BALTIDRIVE®power train utilizes special corrosion resistant materials of construction and state-of-the-art technology to ensure ease of maintenance and reliable year-round performance. This BAC engineered drive system consists of a specially designed powerband and two cast aluminum sheaves located at minimal shaft centerline distances to maximize belt life. As compared to a gear drive system, this specially engineered belt drive system provides many advantages. The BALTIDRIVE® Power Train requires only periodic inspection of components and belt tensioning, which is simple with a single nut adjustment, and requires less downtime. Only fan bearing lubrication is required for routine maintenance. Belt drive systems also have the added advantage of being suitable for variable frequency drive (VFD) applications without requiring expensive optional accessories. |

|||

|

|

|||

|

BALTIDRIVE® Power Train |

|||

|

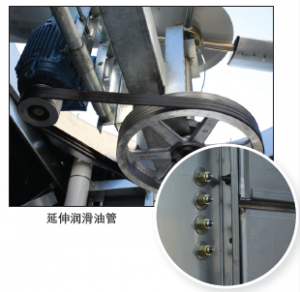

• Independent Fan Operation (Option) The independent fan consists of one fan motor and drive assembly for each fan to allow independent operation, adding an additional step of fan cycling and capacity control. This ensures complete redundancy for the fan and motor system. • Vibration Cutout Switch (Option) A factory mounted vibration cutout switch is available to effectively protect against rotating equipment failure. BAC can provide either a mechanical or solid-state electronic vibration cutout switch in a NEMA 4 enclosure to ensure reliable protection. Additional contacts can be provided on either switch type to activate an alarm. Remote reset capability is also available on either switch type. • Extended Lubrication Lines (Option) |

|||

|

Extended lubrication lines are available for lubrication of the fan shaft bearings. Fittings are located on the exterior casing panel next to the access door. |

|||

|

|

|||