| Q:Why Ice Thermal Storage for District Cooling Projects? |

| A:Because only ice, on a simple and practical basis, can provide a constant 34°F (1°C) supply fluid temperature that yields: |

| 1. Lowest first cost system that does not require utility incentives |

| 2. Reduced energy costs by providing flexibility in when energy is used and reducing the total system kWh usage |

| 3. Reduced maintenance by using smaller equipment with flexibility in service schedules |

| 4. Improved system reliability ensuring constant cooling |

| 5. Space savings with reduced equipment room and heat rejection requirements |

| 6. Environmentally friendly systems with reduced energy consumption and global warming |

Lowest First Cost

|

|

| An ice storage system that takes advantage of low temperature fluid is the lowest first cost design. Substantial savings in the chilled water distribution system are realized when the system design incorporates reduced flow rates that result from using a larger temperature range in the water loop. Use of a 20°F (11°C) temperature range instead of a conventional 10°F (5.6°C) to 14°F (7.8°C) temperature range results in a substantial reduction in pipe size. Smaller distribution piping can often be installed via trenching versures tunneling, allowing the piping to be installed with less time and expense. |

| The savings that result from the use of smaller distribution piping offset the cost of the thermal storage equipment. A 16,000 ton (5,632 Mw) district cooling plant designed with centrifugal chillers using 44°F (7°C) supply water and one with ice storage using 34°F (1°C) supply water were compared. The conventional plant required 30in (762 mm) diameter distribution piping ($7,680,000 installed) versus 18in (457 mm) for the ice storage system ($5,340,000 installed) that yielded savings of $2,340,000. |

|

Cost

|

44°F (7°C) Supply Water System

|

34°F (1°C) Supply Water System

|

|

Chiller Equipment

|

2,960,000

|

2,865,000

|

|

Cooling Towers $ Evaporative Condensers

|

623,725

|

588,838

|

|

Pumping Equipment

|

551,905

|

402,106

|

|

Thermal Storage Equipment

|

N/A

|

2,957,920

|

|

Equipment Rigging

|

206,781

|

289,666

|

|

Mechanical Piping

|

2,560,000

|

2,711,200

|

|

Mechanical Insulation

|

844,800

|

894,696

|

|

Refrigerant

|

224,800

|

73,132

|

|

Refrigerant

|

224,800

|

73,132

|

|

Plant Ventilation

|

16,733

|

99,934

|

|

Automation System

|

993,218

|

1,805,987

|

|

Electrical Equipment

|

2,475,742

|

1,835,634

|

|

Building Cost

|

3,960,000

|

2,645,775

|

|

Sales Tax (Equipment & Material)

|

600,138

|

624,536

|

|

CONSTRUCTION COSTS

|

16,017,042

|

624,536

|

|

Project Management $ Engineering

|

1,927,113

|

2,053,249

|

|

Project Contingency

|

897,208

|

995,401

|

|

TOTAL PLANT COST

|

16,017,042

|

624,536

|

|

Street Distribution Piping Cost Estimate

|

|

|

|

6,000 Linear Feet: Trenching & Restoration

|

5,820,000

|

3,960,000

|

|

12,000 Linear Feet of Supply and Return Piping

|

1,860,000

|

1,380,000

|

|

TOTAL STREET PIPING COST

|

7,680,000

|

5,340,000

|

|

Total Building Connections Cost Estimate

|

|

|

|

Heat Exchangers

|

960,000

|

422,400

|

|

Stations

|

560,000

|

480,00

|

|

Piping, Erection & Insulation

|

2,960,000

|

1,977,600

|

|

TOTAL BUILDING CONNECTION COST

|

4,480,000

|

2,880,000

|

|

16,000 TON COOLING SYSTEM TOTAL

|

31,001,363

|

28,303,324

|

|

Reduced Energy Cost

|

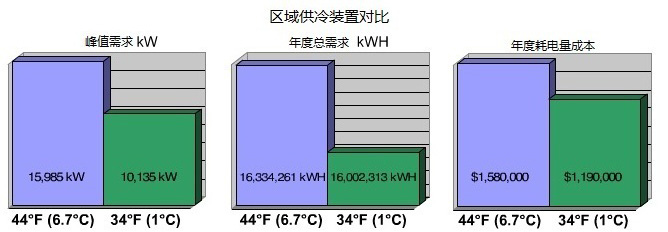

| With smaller mechanical equipment, ice thermal storage can lower electrical demand charges up to 50%. In addition, total annual energy consumption is less because of the lower pumping horsepower (kW). As the electric industry continues to deregulate, and time-of-use rates, real time pricing schedules and negotiated power prices become standard, ice storage can provide even greater future savings in operating costs. |

|

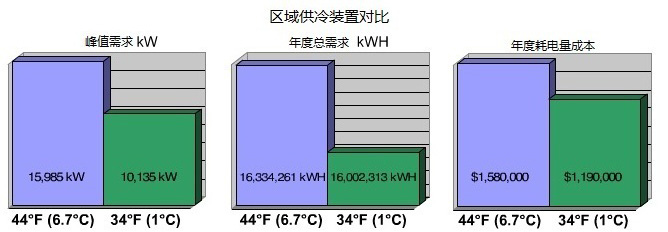

| In a comparison of a 16,000 ton (5,632 MW) district cooling plant designed with centrifugal chillers using 44°F (6.7°C) supply water and one with ice storage using 34°F (1°C) supply water, the peak demand was 15,985 kW for the conventional plant and 10,135 kW for the ice plant, a 37% reduction in peak demand. |

|

Reduced Maintenance

|

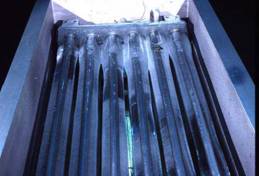

| The ice storage coils have no moving parts so very little maintenance is required. The only ice thermal storage maintenance required includes the air pump, system fluid and controls. Because the chillers, pumps and heat rejection equipment are smaller, the ice storage system will have less maintenance than a conventional system. |

|

|

|

Improved System Reliability

|

|

Ice Storage systems provide the reliability necessary to ensure air-conditioning is available. With conventional systems, installing multiple chillers provides redundancy. In the event of a mechanical failure of one chiller, the second chiller provides limited cooling capacity. The maximum available cooling for the conventional system would only be 50% on a design day. |

|

|

|

| Most ice storage systems utilize two chillers in addition to the ice storage equipment. Two chillers are designed to provide approximately 60% of the required cooling on a design day while the ice storage provides the remaining 40% of the cooling capacity. In the event only one chiller is available to provide cooling during the day, up to 70% of the cooling capacity is available. The one operable chiller provides 30% of the cooling requirement while the ice provides up to 40%. Base on typical HVAC load profiles and ASHRAE weather data, 70% of the cooling capacity would meet the total daily cooling requirements 85% of the time. |

Space Savings

|

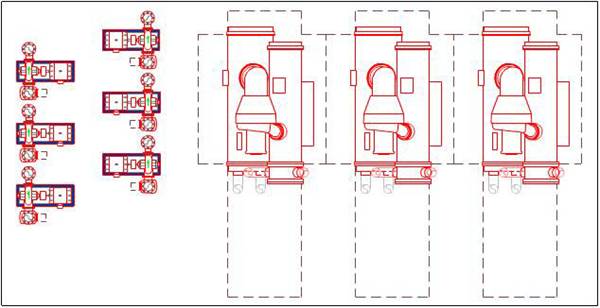

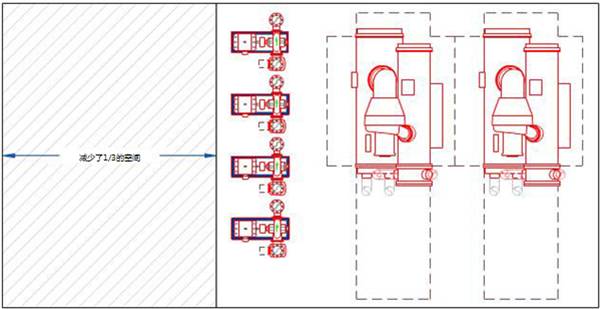

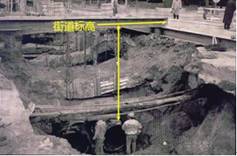

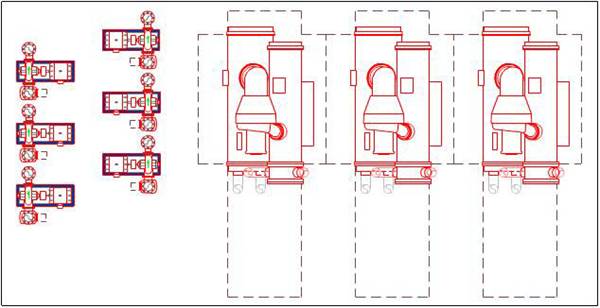

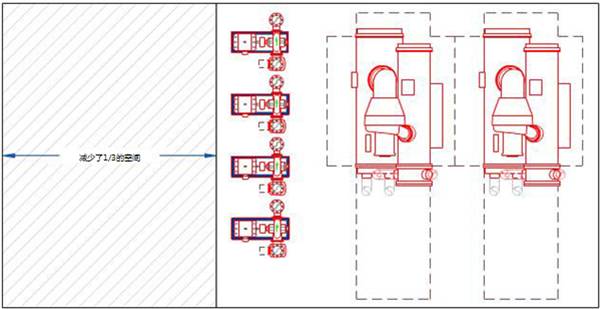

| Ice Thermal Storage saves equipment room and heat rejection space since smaller chillers, pumps and heat rejection equipment is required. A district cooling plant with ice thermal storage requires two-thirds of the chiller and heat rejection capacity of a conventional system. The chilled water pumps will be half the size of a typical 10°F (5.6°C) temperature differential system, and the condenser water pumps will be two-thirds the size of a conventional system. The plan area required for the equipment room and heat rejection equipment can be cut by one-third. The thermal storage can be located outdoors, in a sub-basement or under a parking lot, it does not have to be part of the equipment room.

Chilled water storage requires 4 to 10 times the space of ice thermal storage. The use of sensible cooling combined with storage inefficiencies make chilled water storage tanks larger. |

|

|

|

传统系统的设备室

|

|

|

|

Environmentally Friendly

|

|

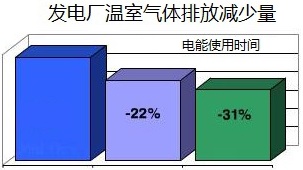

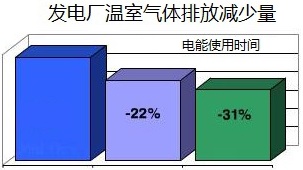

Reducing energy consumption and using electricity at night will reduce global warming. District cooling, using new energy efficient water-cooled chillers and ice storage, will significantly reduce energy consumption. Electricity generated at night generally has a lower heat rate (lower fuel use per power output), and therefore, lower carbon dioxide and greenhouse gas emissions resulting in less global warming.The California Energy Commission concluded that the use of electricity at night created a 31% reduction in air emissions over the use of electricity during the day. The use of an environmentally friendly and energy efficiency ammonia refrigerant, can be considered for may district cooling systems. |

|

|

|

|