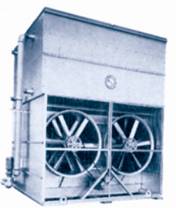

| Principle of Operation

|

| The vapor to be condensed is circulated through a condensing coil,which is continually wetted on the outside by a recirculating water system.Air is simultaneously blown upward over the coil,causing a small portion of the recirculated esyrt yo rbspotsyr. This evaporation removes heat from the coil,cooling,and condensing the vapor in the coil. |

|

| Low Life-Cycle Cost |

| V Evaporative Condensers.Series V Evaporative Condensers are generally lower in first cost than air-cooled condensers or shell-and-tube condenser/cooling tower systems.the condensing systems,and factory-assembled sectional construction minimizes costly field erection time.As a result,B.A.C. series v Evaporative Condensers offer low total installed cost. Blow-through design,a simplified water distribution system,a proven corrosion protection system and other B.A.C. design features minimize maintenance costs.Low first cost and low maintenance cost,combined with the energy savings benefits of evaporative condensers,result in lower life-sycle costs than alternative condensing systems. |

|

| Energy Savings |

| V Evaporative Condensers offer energy savings by providing lower system horsepower than conventional air-cooled and water-cooled condensing systems. |

|

| - Compared to air-cooled system |

| Evaporative condenser capacity is a function of ambient wet bulb temperature while air-cooled condenser capacity is a function of ambient dry bulb temperature. Since design wet bulb temp-eratures are generally 8 to 11℃ lower than design dry bulb temperatyres,system condensing temperatures using evaporative condensing can be 8 to 11℃ less resulting in compressor and system horsepower savings of up to 30 percent. |

|

| - Compared to shell and tube con-denser /cooling tower systems |

| The evaporative condenser rejects heat directly to the ambient air in one step of heat transfer. In the shell-and-tube conden-ser/cooling tower system,heat must be first transferred to the cooling water by the condenser, and then to the atmosphere by the cooling tower .The single heat transfer step in evaporative condensers provides lower condensing temperatures and compressor horsepower savings of up to 15 percent. |

|

| Coil Section |

|

| Typical for models |

| The coil section consists of the condensing coil,the water distribution system and the drift eliminators,enclosed in a heavy-gauge galvanized steel casing.All principal casing panels are formed with double-brake flanges providing maximum strength and rigidity and more reliable sealing at watertight joints. |

|

| The condensing coil is all prime surface continuous serpentine steel tubing and is tested at 375 psig air pressure under water. The coil is designed for low pressure drop with sloping tubes for free drainage of the condensed liquid.The coil is encased in a steel framework and the entire assembly is hot-dip galvanized after fabrication. |

|

| Trouble-Free Water Distribution |

| The water distribution system consists of a galvanized header and large diameter,non-clog, 360° plastic spray nozzles oriented for potimum wetting of the coil under all operating conditions,The nozzles,spray branches,and headers are connected by rubber grommets which permit easy removal for cleaning. |

|

| Eliminators |

| Eliminators are constructed of specially formulated PVC and furnished in easily handled sections.They have a minimum of three changes in air direction with an air deceleration zone to limit drift loss to less than 0.002% of the total water circulated while directing the discharge air away from the fans. |

|

| Pan Section |

| The pan section is a combination pan and fan arrangement with the fans in a blow-through configuration .All structural elements and steel panels are constructed of heavy-gauge galvanized steel .All principal panels are formed with double-brake flanges for maximum structural integrity. |

|

| Ease of Maintenance

|

|

| - Few Moving Parts

|

| Less maintenance is an inherent benefit of B.A.C.′s single fan side design because there are a minimum number of fans,bearings,motors and drives. |

|

| - All Moving Parts Located at Base of Unit |

| All moving parts are located near the base of the unit within easy reach for cleaning,lubrication,or adjustments.Belt adjustment on Series V units is accomplished by a single threaded bolt and nut assembly accessible from outside the fan assembly.Additionally, the axial fan unit features the motors and drives at the front of the unit.Motor and drive maintenance can be performed without having to access the inside of the unit. |

|

| - Easy Pan Access

|

| Large pan space simplifies cleaning the unit interior another inherent benefit of single fan side design. The pan strainer provides a large effective area in a single strong,but lightweight,piece which maintenance personnel can remove for cleaning without entering the sump. |

|

| - Trouble - Free Water Distribution |

| The possibility for scale buildup on the coil is reduced because the spray water flow and nozzle spacing have been selected to ensure complete wetting of coil surfaces during all operating conditions.The patented 360°Spray nozzles are required due to the large orifice, and fewer nozzles are required due to the unique spray pattern.The nozzles and spray branches are grommetted for easy removal. |

|

| - Circular access doors

|

| Circular access doors provide convenient access to the interior of the pan for inspection,adjusting the float valve ,cleaning the lift-out strainers,and flushing the sump. |

|