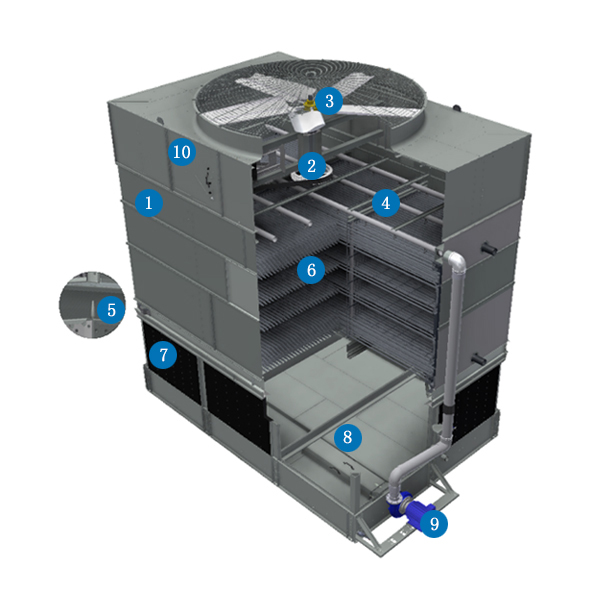

Material of Construction

Standard construction

G235 mill galvanized steel is the heaviest commercially available galvanized steel, universally recognized for its strength and corrosion resistance. To assure long life, G235 mill galvanized steel panels and structural members are used as the standard material of construction. BAC units are certified to withstand up to an SDS of 3.10g and wind loads of 200psf, proving its construction is designed for extreme durability. With proper maintenance and water treatment, G235 galvanized steel will provide an excellent service life under the operation conditions normally encountered in comfort cooling and industrial applications.

Stainless steel (Option)

Two stainless steel material of construction options are available. One is stainless cold water basin, all steel panels and structural members of the cold water basin are constructed from stainless steel and other panels and structural members of the units are still constructed from G235 galvanized steel, Another is all stainless steel construction, all steel panels and structural elements are constructed of stainless steel.

Coil Configurations

Standard serpentine coil

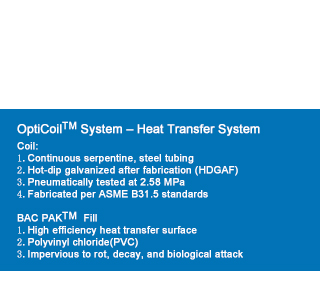

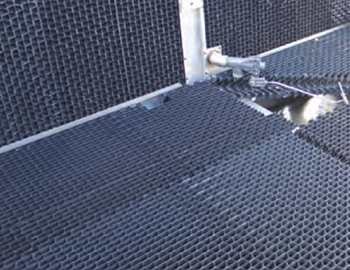

The standard coil is constructed of continuous lengths of all prime surface steel. The coil is hot-dip galvanized after fabrication (HDGAF) to apply a thick, zinc corrosion barrier over the entire exterior surface of the coil. The coil is designed for low pressure drop and for free drainage of fluid. Each coil is pneumatically tested at 2.58MPa and is fabricated per ASME B31.5 standards to ensure the highest quality and complete integrity.

Cleanable header coil (Option)

The cleanable header tube bundle provides removable cover plates on the inlet and outlet header boxes to permit access to each serpentine tube circuit for solvent or air-pressure cleaning. Each coil is pneumatically tested at 860kPa.

Stainless steel coil (Option)

Coils are available in stainless steel for specialized applications. The coil is designed for low pressure drop and for free drainage of fluid. Each coil is pneumatically tested at 2.58MPa and is fabricated per ASME B31.5 standards to ensure the highest quality and integrity.

Stainless Steel Coil Construction

ASME U designator coil (Option)

BAC offers coils that are certified in accordance with the ASME Boiler and Pressure Vessel Code, Section VIII, Division I. ASME U designated coils are available for projects requiring ASME certified pressure vessels and involve 3rd party inspection and certification. Standard ASME U designator coils are rated at 2.34MPa maximum allowable working pressure, and they are pneumatically tested at 2.58MPa.

Multiple circuit coils (Option)

Split coil configurations are available to allow separate process fluid loops through the same unit. Separate loops may be needed for multiple applications requiring different temperature processes or multiple types of process fluids.

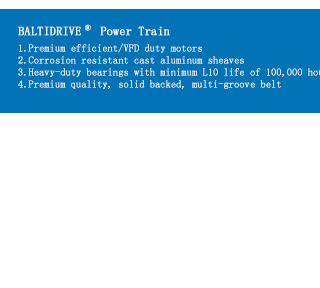

Drive System Options

Standard BALTIDRIVE® power train

The BALTIDRIVE® power train utilizes special corrosion resistant materials of construction and state-of-the-art technology to ensure ease of maintenance and reliable year-round performance. This BAC engineered drive system consists of a specially designed powerband and two cast aluminum sheaves located at minimal shaft centerline distances to maximize belt life. When compared to a gear drive system, this specially engineered belt drive system provides many advantages. The BALTIDRIVE® power train requires only periodic inspection of components and belt tensioning, which is simple with a single nut adjustment and requires less downtime. Belt drive systems also have the added advantage of being suitable for variable frequency drive (VFD) applications without requiring expensive optional accessories.

BALTIDRIVE® Power Train

Standard extended lubrication lines

Extended lubrication lines are available for lubrication of the fan shaft bearings. Fitting are located on the exterior casing panel next to the access door.

Independent fan operation (Option)

Two fan PFi-1218 and PFi-1236 models are available for added redundancy and capacity control. The two fan drive system consists of one fan and drive assembly for each fan to allow independent operation.

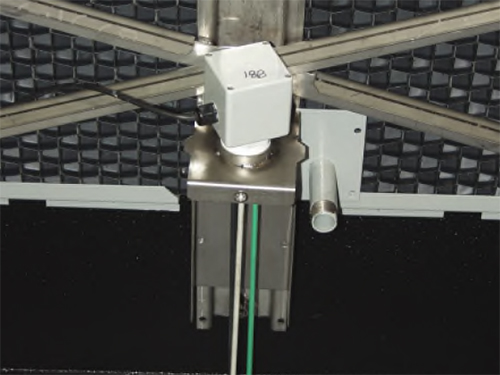

Vibration cutout switch (Option)

A factory mounted vibration cutout switch is available to effectively protect against rotating equipment failure. BAC can offer either a mechanical or solid-state electronic vibration cutout switch in a NEMA 4 enclosure to ensure reliable protection. Additional contacts can be provided on either switch type to activate an alarm. Remote reset capacity is also available on either switch type.

Vibration Cutout Switch

Automatic bearing greaser (Option)

Automatic bearing greasers come with BAC recommended grease, compatible with all BAC bearings and provide a continuous supply of new grease to eliminate the need for periodic bearing maintenance. Life of the bearing is extended by eliminating under and over greasing problems.

Automatic Bearing Greaser

Cold Water Basin

Standard mechanical water level control

Mechanical make-up valves must operate continuously in the moist and turbulent environment within evaporative cooling equipment. Due to this environment, the operation of the valve must be simple and the valve must be durable. BAC’s high quality mechanical water level control assembly is standard with all units and has been specially designed to provide the most reliable operation while being easy to maintain.

Mechanical Water Level Control

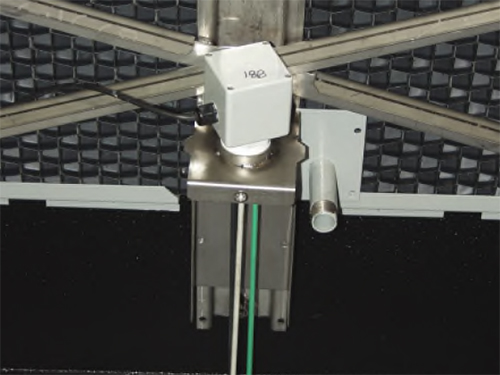

Electric water level control (Option)

BAC’s electric water level control (EWLC) is a state-of-the-art, conductivity actuated, probe type liquid level control. The hermetically sealed EWLC is engineered and manufactured specifically for use in evaporative cooling systems and is equipped with an error code LED to indicate status, including when the water and/or proves are dirty. The EWLC option replaces the standard mechanical make-up valve and includes a slow closing, solenoid activated valve in the make-up water line to minimize water hammer. EWLC is recommended when more precise water level control is required and in areas that experience sub-freezing conditions.

Electric Water Level Control

Basin sweeper piping (Option)

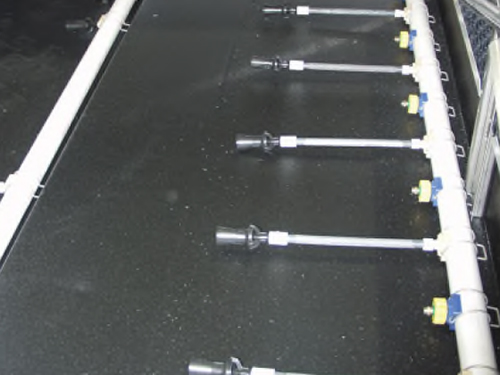

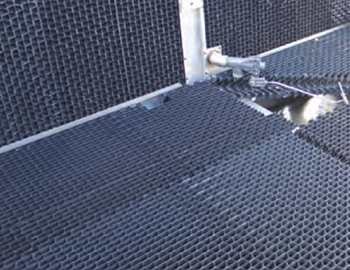

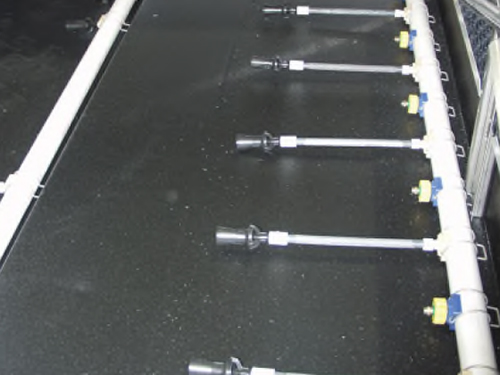

Basin sweeper piping is an effective method of eliminating sediment that may collect in the basin. A complete piping system, including nozzles, is provided in the basin to connect to side stream filtration systems.

Basin Sweeper Piping

Low and high level alarm float switch (Option)

Low and high level alarm float switches are available to provide added control to your equipment operation. Level alarms can alert operators to and abnormal operating condition to ensure the highest system efficiency with minimal water usage.

Basin heaters (Option)

Evaporative cooling equipment exposed to below freezing ambient temperatures require protection to prevent freezing of the water in the cold water basin when the unit is idle. Factory-installed electric immersion heaters, which maintain 4.4°C water temperature, are a simple and inexpensive way of providing such protection.

Basin Heater

Sound Options

Standard fan

The fan provided for all PFi closed circuit cooling towers is selected to optimize low sound levels and maximize thermal performance. Thermal performance with the standard fan has been certified in accordance with CTI standard STD-201.

Low sound fan (Option)

The low sound fan option reduces sound level. Adding a high solidity fan allows for decreased fan speed, which proportionally decreases sound levels. Thermal performance with the low sound fan has been certified in accordance with CTI standard STD-201.

Low Sound Fan

Whisper quiet fan (Option)

The whisper quiet fan reduces sound level further. This single piece, high solidity fan is made from chemical resistant fiber reinforced polyester (FRP) and comes standard with blade leading protection. As a single piece fan, the non-corrosive blades are permanently pitched and require minimal maintenance. Thermal performance with the whisper quiet fan has been certified in accordance with CTI standard STD-201.

Water silencers (Option)

Water silencers are available to reduce the sound of falling water inherent in induced draft counterflow evaporative cooling towers. Thermal performance with the water silencers has been certified in accordance with CTI standard STD-201.

Water Silencers

Air Discharge Options

Fan cowl extensions (Option)

Fan cowl extensions allow for unobstructed airflow on the discharge side, which help ensure that the units are providing maximum capacity. When closed circuit cooling towers cannot be located above adjacent structures, fan cowl extensions will be necessary so that discharge air flows out of the tower properly and is not circulated back toward the air intake by the combination of wind pressure and adjacent structures.

Access Options

Motor removal Davit (Option)

All motor removal system options include davit arm(s) to facilitate motor replacement.

Motor Removal Davit Arm

Modular external platforms and ladder packages (Option)

Every modular external platform is pre-assembled and pre-fitted at the factory to ensure that every component will fit and function exactly as described. The platform is rigged easily in the filed with minimum fasteners and drastically reduces the time required for rigging eternal access platforms.

Modular External Platform with Ladder and Safety Cage