| Ice can provide a system that yields: |

- ·Lowest first cost system that does not require utility incentives

- ·Reduced energy costs by providing flexibility in when energy is used and reducing the total system kWh usage

- ·Reduced maintenance by using smaller equipment with flexibility in service schedules

- ·Improved system reliability ensuring constant cooling

- ·Increased comfort from constant supply temperature

- ·Space savings with reduced equipment room and heat rejection requirements

- ·Environmentally friendly systems with reduced energy consumption and global warming

|

Lowest First Cost Design

|

| Air conditioning systems with ice storage can be installed at the same or less first cost than traditional conventional systems if the system takes advantage of the colder supply water available from ice. The savings that result from the use of smaller chillers and cooling towers, reduced pump and pipe sizes and less connected horsepower offset the cost of the ice thermal storage equipment. |

Smaller Chillers and Cooling Towers

|

|

By designing the system around 24-hour per day chiller operation, the size of the chillers and cooling towers required for an ice system is significantly reduced when compared to conventional chillers and heat rejection equipment sized for the instantaneous peak load. A typical thermal storage design includes chillers that provide 50 to 60% of the peak cooling load. The balance of the cooling requirement is provided from the ice storage system. |

|

Reduced Pump and Pipe Sizes

|

|

|

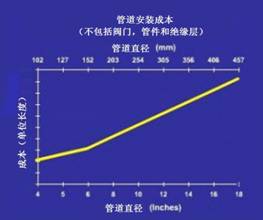

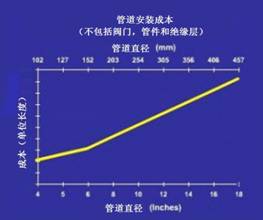

Pump and pipe sizes are also reduced in a properly designed ice storage system. Substantial savings in the chilled water distribution loop are realized when the system design incorporates reduced flow rates that result from using a larger temperature range in the water loop. Use of a larger temperature range, for example 18°F (10°C) instead of the more traditional 10°F (5.5°C) temperature range results in a reduction of pipe size. Condenser water pipe sizes are reduced due to lower flow requirements for the smaller chiller. Pump savings due to reduced chilled water and condenser water flow rates are also realized. |

|

Reduced Cooling Coil and Supply Air Fan Sizes

|

Cooling coils sized using lower supply water temperatures and traditional supply air temperatures are generally smaller due to fewer rows. The reduction in rows leads to lower supply fan HP (kW).

|

| Reduced Air Handling Equipment |

|

|

When the air distribution is designed with lower supply air temperature, the size of the ductwork, fans, and fan motors are reduced. |

|

- Reduced Electrical Distribution

|

|

Smaller chillers, heat rejection equipment and pumps require less horsepower than a traditional system, which results in smaller transformers, switchgear, wire sizes and starter panels.

|

|

Reduced Generator Size

|

| If a facility has a generator for daily or back-up power, the size of the generator will be significantly reduced when the peak electrical load of the facility is reduced using ice storage. The savings associated in a properly designed ice storage system are substantial. The cost of the thermal storage equipment is more than offset by the savings described above. |

Reduced Energy Cost

|

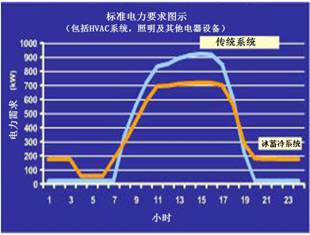

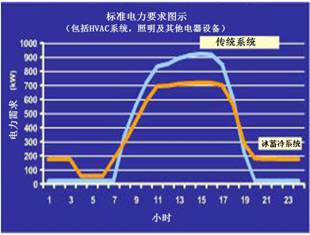

| An ice thermal storage system reduces peak demand, shifts energy usage to non-peak hours, saves energy, and reduces energy costs. |

|

With less connected horsepower, ice storage can lower peak electrical demand for the HVAC system by 50% or more. Since most electrical rates include demand charges during peak demand times and/or higher day versus night kWh charges, savings on electrical bills can be substantial. Peak electrical demand rates of $15 to $18 per kW are not uncommon. In areas with “real time pricing”, where the electric rate varies hour by hour based on the market price of electricity, day-to-night kWh costs can vary by 500 to 1000%. The use of electricity at night versus peak daytime hours can lead to large savings on energy bills.

|

|

Energy Saving

|

| In addition, total annual kilowatt-hours used are less when the system is designed taking advantage of the low supply water temperature available from the ice storage system. Lower kWh consumption is possible for five reasons: |

- 1. Although making ice requires more energy than producing chilled water, the efficiency penalty is not as large since the ice is made at night when condensing temperatures are lower, increasing the efficiency of the chiller.

|

- 2. Ice systems typically operate the chiller at full load. Chillers are very inefficient when run with low loads during the Spring and Fall. A typical chiller will operate at less than 30% capacity for half the year.

|

- 3. Reduced pumping horsepower.

|

- 4. Reduced fan horsepower due to lower air pressure drop across the cooling coil. A higher chilled water temperature differential across the cooling coil usually results in fewer rows, and therefore, a lower pressure drop.

- 5. The ability to recover waste heat from the chiller for heating water both night and day.

|

| Additional kWh savings are possible if the airside distribution is designed taking advantage of the low temperatures available from the ice storage system. As the electric industry continues to deregulate, and time-of-use rates, real time pricing schedules and negotiated power prices become standard, ice storage can provide even greater future savings in operating costs. |

Reduced Maintenance

|

|

The ice storage coils have no moving parts so very little maintenance is required. The only ice thermal storage maintenance required includes the system fluid, controls, and water level. Because the chillers, pumps and heat rejection equipment are smaller, the ice storage system will have less maintenance than a traditional system. The ice storage system also allows a chiller to undergo routine maintenance during the day when the ice storage can handle the system load. |

|

|

|

|

Improved System Reliability

|

| Ice storage systems provide the reliability necessary to ensure air-conditioning is available. With conventional systems, installing multiple chillers provides redundancy. In the event of a mechanical failure of one chiller, the second chiller provides limited cooling capacity. The maximum available cooling for the conventional system would only be 50% on a design day. |

|

Most ice storage systems utilize two chillers in addition to the ice storage equipment. Two chillers are designed to provide approximately 60% of the required cooling on a design day while the ice storage provides the remaining 40% of the cooling capacity. In the event only one chiller is available to provide cooling during the day, up to 70% of the cooling capacity is available. The one operable chiller provides 30% of the cooling requirement, while the ice provides up to 40%. Based on typical HVAC load profiles and ASHRAE weather data, 70% of the cooling capacity would meet the total daily cooling requirements 85% of the time.

|

|

Increased Comfort and System Flexibility

|

| Increased comfort comes from a constant, chilled water supply temperature throughout the day without cycling on and off to meet the load requirements. |

| The lower humidity resulting from lower supply air temperatures provides increased comfort as well as improved air quality and freshness. Typically, in a cold air system with 45°F (7°C) supply air, the space’s relative humidity will be approximately 10% lower than in a similar 55°F (13°C) system. Studies have show that if the space humidity is lowered while the space dry bulb temperature is held constant, occupants feel more comfortable. A more comfortable working environment can also translate into increased employee productivity. |

Space Saving

|

| Ice thermal storage saves equipment room and heat rejection space since smaller chillers, pumps, and heat rejection equipment are required. A typical building with ice thermal storage requires one half the chiller and heat rejection capacity of a traditional system. The chilled water pumps will be half the size of a typical 10°F (5.5°C) temperature differential system and the condenser water pumps will be half the size of a traditional system. The plan area required for the equipment room and heat rejection equipment can be cut by one third. The thermal storage units can be located outdoors, in a sub-basement, or under a parking lot; it does not have to be part of the equipment room. |

| If low temperature air is used, the air handling equipment and ductwork will be smaller. The smaller ductwork can allow a reduction of 3 to 6 inches (76 to 152 mm) in ceiling height, while reducing other building structural costs due to reduced size and weight. |

| Chilled water storage requires 4 to 10 times the space of ice thermal storage. The use of sensible cooling combined with storage inefficiencies make chilled water storage tanks larger. |

Environmentally Friendly

|

|

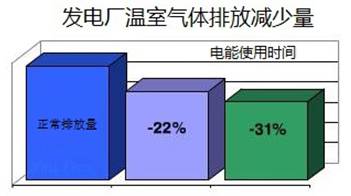

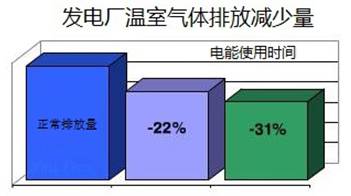

Reducing energy consumption and using electricity at night will reduce global warming. Electricity generated at night generally has a lower heat rate (lower fuel use per power output), and therefore lower carbon dioxide and greenhouse gas emissions resulting in less global warming. |

|

|