| Operating Mode |

| Hot gaseous refrigerant in the coil transfers heat to spray water and air outside the coil,being cooled into liquid.The draught fan produces extra forced air that enables spray water to cover the coil surface thoroughly,thus resulting in remarkable improvement in heat~exchange performance.Whlie spray water and air absorbs heat.the water partly turns into vapor due to its increased temperature. Therefore, a great deal of heat is taken up by the latent heat of vaporization.Water out of the heated air is baffled to the PVC heat-exchange fill.Cooled by air across the PVC heat~exchange fill to a lower temperature, water flows into the water sump where it is pumped to the spray system for repeating circulation.A water level controller is designed to control the water makeup for water dispersed into surrounding air. Tbe capacity of the evaporative condenser can be adjusted by variable motor speed or different combination of air fan and motor depending on actual demand for load. |

|

|

| Advantages Structural |

|

| 1. Reduced Scale Tendency |

| Four facets of the CXV Evaporative Condenser work together to reduce the proponsity for scale build-up when compared with conventional condensers: |

|

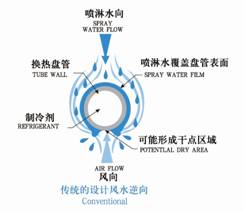

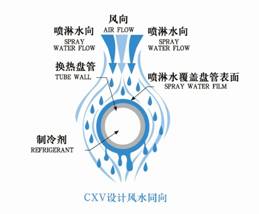

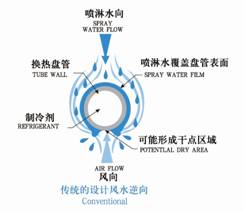

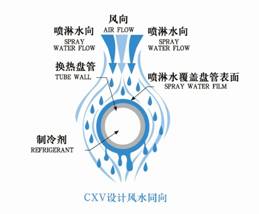

| - Air and Water Flow in Parallel Path |

| Better water coverage around the tubes is due to air and spray water flowing in fl smooth,parallel,downward path over the condensing coil,maintaining full tube coverage.This parallel flow eliminates scale-promoting dry spots since the water is not stripped from tile underside of the tubes by the airflow. |

|

|

| - Increased Water Flow over Coil. |

| The spray water flow rate over the coil is more than twice that of most conventional evaporative condensers.This provides continuous flooding of the primary heat transfer surface for decreased scaling potential.No increase in pump horsepower is required with this higher flow due to the CXV’s unique heat transfer system. |

|

| - Evaporation Occurs Primarily in Wet Deck |

| The CXV incorporates combined-flow technology using both primary and secondary heat transfer surfaces.The primary heat transfer surface,the serpentine condensing coil,is the most important as well as the most expensive component in the evaporative condenser.The coil of the CXV is protected from detrimental scale since the CXV coil relies primarily on sensible heat transfer and therefore is less susceptible to scale formation than are other designs that rely primarily on 1atent (evaporative)heat transfer from the coil surface. |

|

| - Colder Spray Water |

| Spray water at colder temperatures has a lower propensity to form scale because scaling compounds remain in solution rather than depositing as solids on the coil,In the CXV,the spray water over the coil is commonly 4-5℃ colder than other condenser designs due to the addition of the secondary heat transfer surface.The colder spray water alone typically reduces the scaling potential of the CXV by 25% compared to other designs.This is above and beyond the reduction achieved due to the first three facets discussed above. |

|

| 2. BACross® wet Deck Surface(Patented) |

|

| An efficient polyvinyl chloride(PVC)wet deck surface designed.manufactured.and tested by B.A.C.is an integral component of the Series CXV Evaporative Condenser’s innovative heat transfer system.The wet deck surface is impervious to rot,decay,biological attack. Series CXV Evaporative Condenser utilize the BAC-developed high efficiency BACross Wet Deck Surface with Integral Eliminators which provides maximum air/water contact time and low air pressure drop to ensure efficient heat transfer with minimum fan power requirement. |

|

|

| 3. Wide-Spaced,Non-clog Air Inlet Louvers |

|

| Durable,wide-spaced air inlet louvers reduce the potential for performance-robbing scale build-up and damaging ice formations at the air/water interface. |

|

| 4. Condensing Coil |

|

| The condensing coil is factory-assembled from high-quality steel tubing.The condensing coil has a design pressure of 2.0 MPa. It is tested by an encircling eddy current system and also at 2.5 MPa air pressure under water.The coil is designed with sloping tubes for free drainage Of the condensed liquid.The coil is encased in a steel framework and the entire assembly is hot-dip galvanized after fabrication. |

| Coils are also available in stainless steel and aluminium for that are not compatible with the standard galvanized steel construction. |

|

|

| 5. Eliminators |

|

| Constructed of PVC and furnished in easily removable sections for quick access to the coil section,the eliminators impart three distinct changes in air direction in effectively strip moisture from the air stream 1eaving the coil with minimum air resistance. |

|

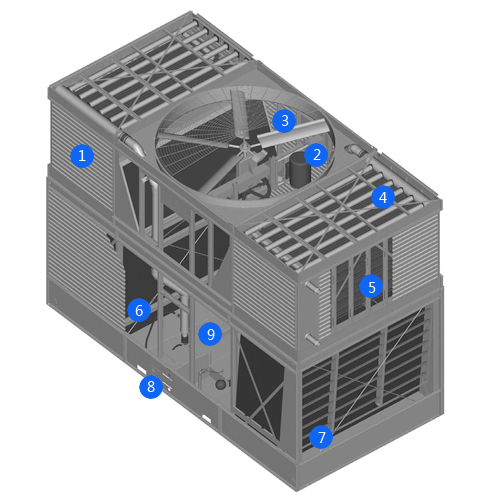

| 6. Fan,Fan cylinders and Fan Shaft Bearings |

|

| Heavy duty,aluminum axial-flow fans have been selected to achieve very low fan motor horsepower.The air is discharged through fan cowls designed for stream-lined air entry and minimum tip clearances for maximum fan efficiencies.Heavy gauge,hot-dip galvanized fan guards are mounted on top of the fan cylinders. |

| Fans and shafts are supported by heavy duty,self-aligning,grease lubricated ball bearings with moisture proof seals and integral slinger rings Bearings ale selected for a minimum LIO life of 40,000 hours. |

| The solid-backed,multigroove,neoprene/polyester belt is manufactured to stringent B.A.C. specifications,and the driver and driven fan sheaves are corrosion-resistant,extending belt life significantly.Belt tension is easily adjusted by means of a simple,threaded bolt-and-nut arrangement on the motor base support assembly.Together,these components provide a highly-reliable system with low maintenance. |

|

|

| 7. Water Distribution System |

|

| A galvanized header and Schedule 40 PVC spray branches with large diameter,non--clog,360°plastic spray nozzles are designed for optimum wetting of the coil under all operating conditions. The nozzles,spray branches,and headers are connected by rubber grommets which permit easy removal for cleaning. |

|

|

|

| Maintenance Advantage |

|

| 1. Superior Maintenance features |

|

| The CXV delivers unique and valuablefeatures using proven components.The many maintenance and accessibility features of the CXV eliminate cramped spaces and limited accessibility to~rvice points associated with conventional evaporativecondensers.The CXV design builds upon decades of operating experience,incorporating components that are proven t be durable and simple to maintain. |

|

|

| 2. Direct Access To Water Spray System |

| The parallel air and water flows of the CXV allow the spray area to be uncovered(drift eliminators are inside),permitting quick and easy inspection of tile sprays and coils from outside the unit while the CXV is in full operation. |

|

|

| 3. Hinged Access Doors for Easy Entry |

|

| Oversized access doors in end wall provides easy access to the unit interior. |

|

|

| 4. Easy Access to Fan Drive System and Condensing Coil |

| A spacious plenum provides esay access to the fan drive system and the condensing coil through easily PVC eliminators. |

|

| 5. Sloped Basin Floor Facilitates Cleaning |

| The floor of the water basin is sloped toward the depressed section and the wet deck is elevated to facilitate flushing dirt and debris from this critical area. |

|