| ISO 9001 Certification: |

|

|

|

|

| It confirms BAC’s commitment to quality assurance and reaffirms that BAC meets international standards set for management principles,deigns,closed-loop corrective action,training,and documentation control in all of its engineering and manufacturing operations. |

|

|

| CTI Certified Thermal Performance: |

| The thermal performance of FXV Closed Circuit Cooling Towers has been certified by the Cooling Technology Institute in accordance with its standard STD-201.CTI Certification assures that the published thermal capacity accurately reflects actual unit performance and eliminates the need for costly field performance testing of individual units.BAC was the first manufacturer of closed circuit cooling towers to have ratings independently certified,and the only manufacturer to have all of its current closed circuit lines certified. |

|

|

| Three-year Mechanical Equipmipment Maintenance: |

|

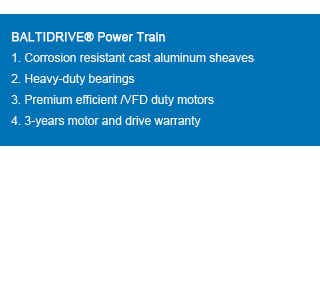

| The Three-year Maintenance provided on FXV Closed Circuit Cooling Towers is the most comprehensive fan motor and mechanical equipment warranty available in the industry.Included in the three-year Maintenance are mechanical equipment supports,fans,fan shafts,bearings,sheaves,and fan motors. |

|

| Reliable Year-Round Operation |

| Separate air inlet 10uvers minimize tendency for scale and ice formation in wet deck. |

| BALTIDRIVE® Power Train utilizes special corrosion-resistant materials of construction and state-of-the-art technology to ensure ease of maintenance and reliable year-round performance. |

|

| Low Installed Cost |

|

| a. Reduces required piping and system complexity. |

| b. Modular design reduces assembly time. |

| c. Reduced weight simplifies rigging and lowers supporting steel costs. |

| d. Motors and drives are factory installed and aligned. |

| e. Fewer coil connections reduces piping costs. |

|

|

|

| 2. Smaller Footprint |

| Effectively combines the function of a cooling tower and heat exchanger into one piece of equipment. |

| Reduced pump and pipe sizes required to serve process load. |

|

| 3. Lower Operation Cost |

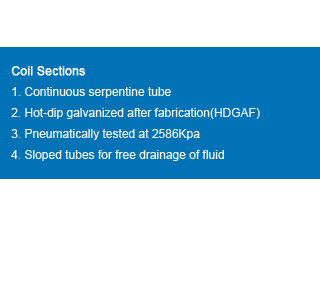

| a. Patented Combined Flow Technology |

| b. Energy-efficient,axial fans |

| c. Capacity certified by CTI |

|

Easy Maintenance

|

| The FXV utilizes unique features to increase the accessibility of the unit’s main components.These features eliminate cramped spaces with most service points accessible from outside of the unit.The FXV design builds upon years of operating experience and was designed with input from service personnel. |

|

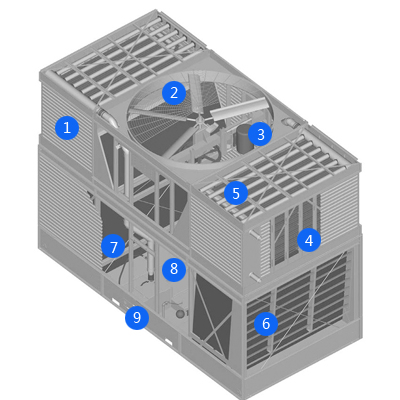

| 1. Hinged Access Doors for Easy Entry

Provides easy access to unit interior. Standard on both end walls.Easy latch,inward swinging. |

|

|

|

| 2. Spacious Unit Interior

Provides easy access to fan drive system and heat transfer coil.Basin floor is sloped toward the drain to facilitate cleaning.Internal walkway provides a dry working area. |

|

| 3. Access to Spray Distribution During Full Operation

Parallel flow of air and water allow inspection during full operation.Top of coil is accessible during full operation. |

|

|

|

| Application Wide |

| Ideal for difficult thermal duties(close approach or high range) |

| 1. Ideal for replacement applications |

| 2. Compact size and low sound levels simplifies layout |

| 3. Optional coil materials and configurations to meet special needs. |

|